One Stop Shop for UID and RFID Compliance:

Lasers/Scanners/Verifiers/Validation/Ink and Chemical Etch Stencils/WAWF and UID Registry Upload

Hand Held Verifier

DPM Verifier

Have you attended UID conferences only to go home more confused?

or

Have you researched the net and found that all vendors mention that all you need is their system and you are in compliance with Mil Std 130?

Our specialty is educating and providing full turn-key systems to comply to UID standards or you may like us to provide the UID service where we can mark tags or DPM (direct part mark) and send all tags or parts back to you with 100% verification.

We understand that practical UID usage will vary with every company and we will discuss your specific requirements and demonstrate equipment so you may see first hand what is needed to comply and satisfy the Mil Std 130 mandate.

We work with all vendors therefore let us know if you have a specific vendor of choice such as a scanner or thermal printer and we will be happy to quote that particular vendor’s equipment.

If you prefer to purchase equipment to bring UID in house then we will discuss the best marking method which can include lasers, dot peen, ink stencil, ink jet, chemical etch or a photo chemical process.

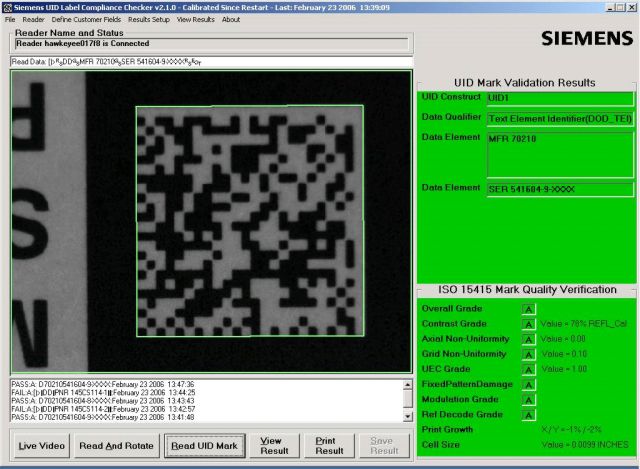

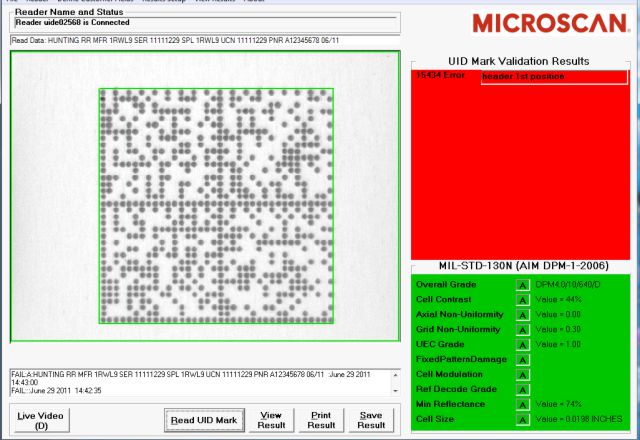

Then we will discuss scanning and include validation and verification. These two words sounds alike, but they are very different. Validation refers to how the syntax relates to the 15434 spec in order to meets Mil Std 130 compliance. Verification refers to the actual image and how it relates to the 15415, AS9130 or AIM DPM spec to satisfy Mil Std 130.

Then we will discuss if you have needs to upload to the WAWF (Wide Area Workflow) and also if you need to upload your UID to the government registry. We have affordable and unique solutions for easy ways to do both.

What YOU need to comply to UID:

Marking the part either directly or by attaching a tag

Choose marking device of choice

Laser, chem etch, ink stencil, dot peen, ink jet

Or choose tag material of choice

Anodized aluminum, Steel, polyester, Alumamark, TESA Tape, 3M Material

Mark a 2D Data matrix code – square or rectangular as part allows

Scanning

Validation

Verification

Now offering scanners to parse UII data into data fields such as in Excel

Upload

WAWF

Gov’t registry

Make an unreadable mark become a Grade “A” verifying scan without remarking

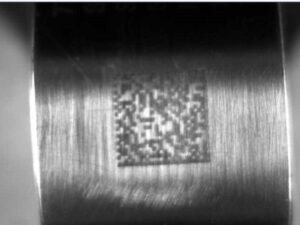

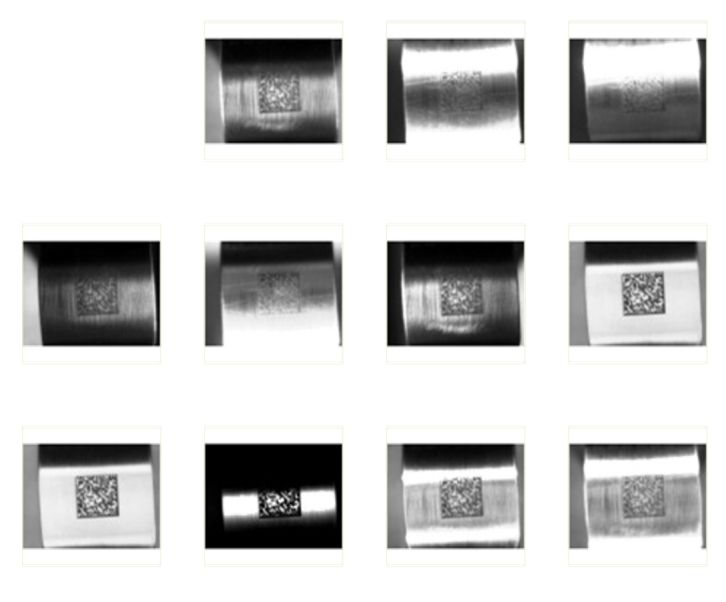

This image will never verify. Notice the brush marks and also the image is not withinn the glare zone. The reader will not read the code that is outside the glare zone.

This is the same part and same image but only the light angle has changed. Notice the brush marks are not noticeable and the part appears to be flat and well within the glare zone and will verify to UID specifications.

DPM Verifier makes it easy to Verify and Validate

These images (above) are all of an identical, brushed steel part. The part is curved. The DPM verifer is unique because it can verify 2D code and UID and change lighting angles. Changing lighting angles became legal in Mil Std 130 in Rev M change 1 and helps to flatten the part using light and also helps to normalize the image. Notice some images show the brush marks in the steel while some images do not.

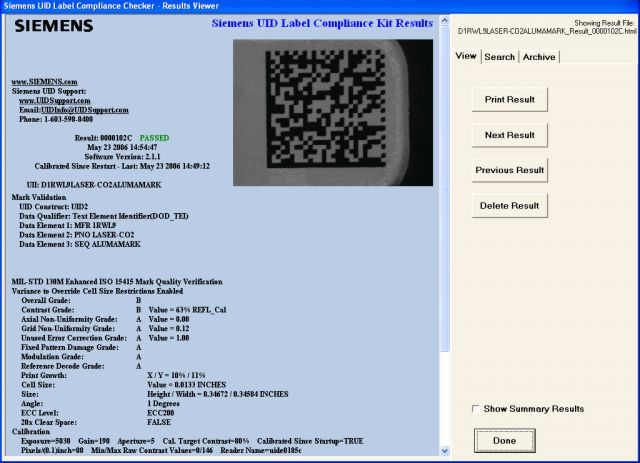

This image is taken from the DPM software. The top portion shows the validation. Validation deals with UID syntax. The bottom portion is for verification. The weakest grade also becomes teh overall grade.

This image shows a dot peen mark. The mark image verify’s to UID standards, but it does not validate to UID standards.

This image shows the DPM verifer on an adjustable stand.

Cylinders should be marked using a Data Matrix rectangle instead of a square to shorten the distance around the circumference. The part, most likely, will not need to be rotated during the marking sequence since the reader can only read information in the “glare” zone anyway. This keeps the marking process much easier.

Verification Report

| Indirect Marking (Tags or Labels) | Marking Method |

|---|---|

| TESA Tape | Most Lasers |

| 3M Material | Most Lasers |

| Anodized Aluminum | Most Lasers |

| Alumamark | C02 Laser |

| Metal Photo | Photo Chemical |

| Polyester Labels | Thermal Printer |

| Steel or Any Metal other Metal Tag | Fiber or YAG laser |

| Steel or Any Other Metal TAG | Thermark or Cerdec with C02 Laser |

| (DPM) Direct Part Marking | Marking Method |

|---|---|

| Plastics - polycarbonate, Lexan, ABS, PEEK, etc | YAG, Fiber or Vanadate Laser, Dot Peen, ink stencil, Ink Jet |

| Plastics - acrylic | C02 laser, Dot Peen, Ink Stencil, Ink Jet |

| Bare Metals | YAG, Fiber or Vanadate lasers, Chem etch, Ink Jet, Ink Stencil, C02 la ser using Thermark or Cerdec |

| Coated Metals (anodized, power coated or painted) | C02, YAG, Fiber or Vanadate lasers, Ink stencil, Ink Jet |