Scroll Through to the Different Machines

This section shows common options for many machines

1

Power cord plugs for 40-80 watts are 5-20 plugs. Adapter for about $10 from Conntek PN 30129 to convert to std 5-15 plug can be purchased, but code is to change the breaker and the wall receptacle

2

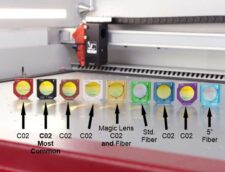

Lens Options – One lens comes with any Trotec laser system purchase. Smaller lenses have a sharper point but atthe expense of focus depth. A larger lens stays in focus longer. Example: engrave around a baseball farther

3

Rotary Indexer – shown with cones. Optional rollers and 3 jaw chuck. This option will allow 360 degree cutting or engraving around cylindrical objects such as a wine glass or bottle

4

Gas assist – option instead of built in air pump. Customer supplies air compressor and oil free air to the regulator (shown)

5

Customer supplies a .25″ hose from the compressor

6

Gas assist option includes a regulator, gauge and a last stage oil seperator and also an internal solenoid to automatically turn air On and OFF

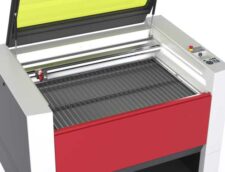

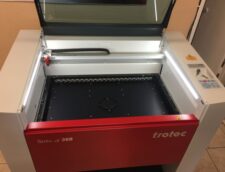

300 Series

1

Air assist pump is built in and is electrically integrated. Air pump is needed for cutting in order to supress flames. In the Trotec system, the air pump helps to keep the lens clean

2

Air pump automatically cycles when programmed in the printer driver

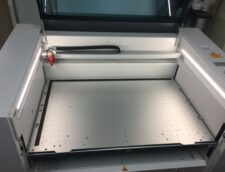

3

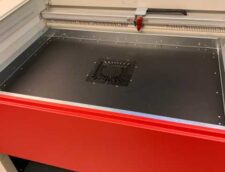

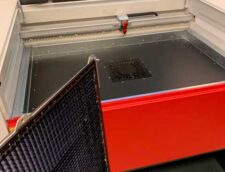

Honeycomb cutting table – used for cutting and is needed to suspend the material so that the cut debris is allowed to fall. This will help keep the bottom side of your material clean

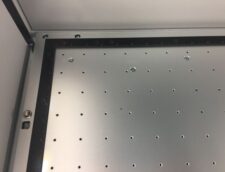

4

Vacuum downdraft table – can hold thin materials down and when combined with using the cutting table can provide a down draft that is betterforrcutting thick acryclics, etc

5

Rotary Indexer – shown with cones. Optional rollers and 3 jaw chuck. This option will allow 360 degree cutting or engraving around cylindrical objects such as a wine glass or bottle

Max diameter with cones = 7.24″

Max diameter with rollers = 3.70

360 Series Laser

1

SP360 shown with magnetic, solid steel table. Downdraft can be seen but not used because the table is solid

2

SP360 shown with object passing through the system – front to back

3

SP360 shown with back panel access panel removed and with an object passing through

4

SP360 shown with back access panel removed. Exhaust must be connected by user

5

SP360 Height – Approx 39″

6

SP360 Width – 48″

7

SP360 Depth – 30.5″ Designed to roll through a

standard door

8

Black Grid Table with .5″ spacing

9

Black Grid Table with .5″ spacing

10

sp360 without any tables.

11

Vacuum table installed

12

Vacuum table close up

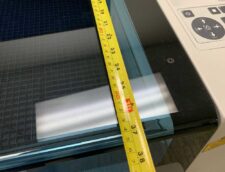

400 Series Laser

1

400 series vacuum table

2

400 series vacuum table close-up

3

400 series vacuum table – shown outside for better visual of the table and how easy it is to remove the different table options

4

400 series black grid table – most universal table

5

400 series honeycomb on top of the vacuum table

6

400 series honeycomb table on top of the vacuum table – close up

7

400 series steel table

8

400 series black aluminum grid .5″ grid spacing (see photo 4)

9

400 series with lamellas (for cutting)

10

400 series main exhaust

11

400 series down draft exhaust

(360 actual shown)

12

400 series back – 3″ or 4″ main and down draft exhaust

13

400 series optional fume system with main exhaust and down draft hoses shown

14

400 series keypad

15

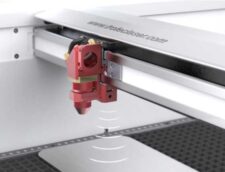

400 series laser head with Flexx lens – shown

16

sp400 width = 56″

17

sp400 depth = 37.5″

18

sp400 pass though option