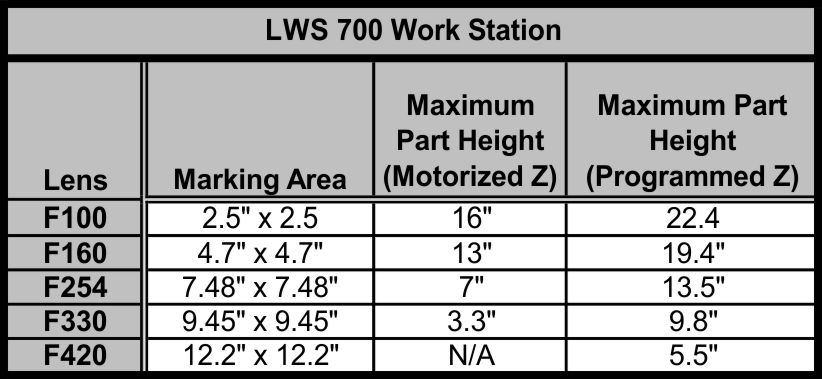

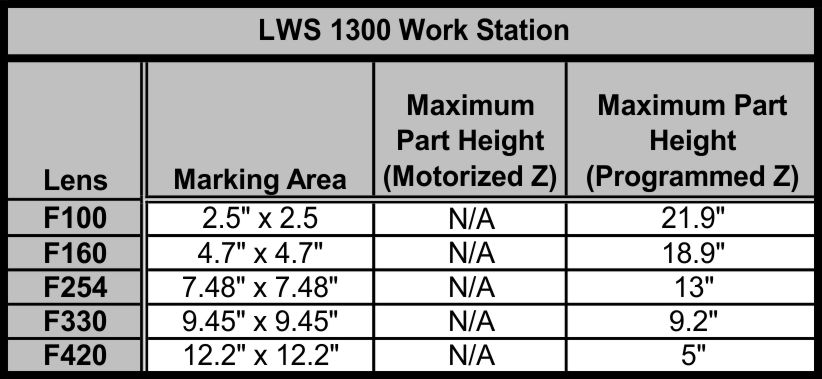

Galvo Laser Options:

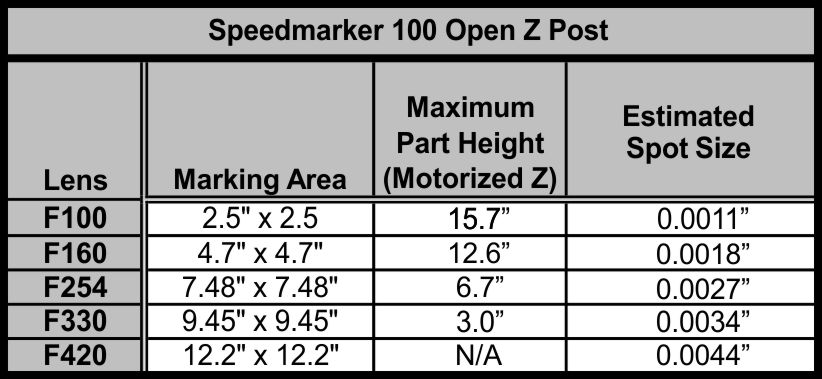

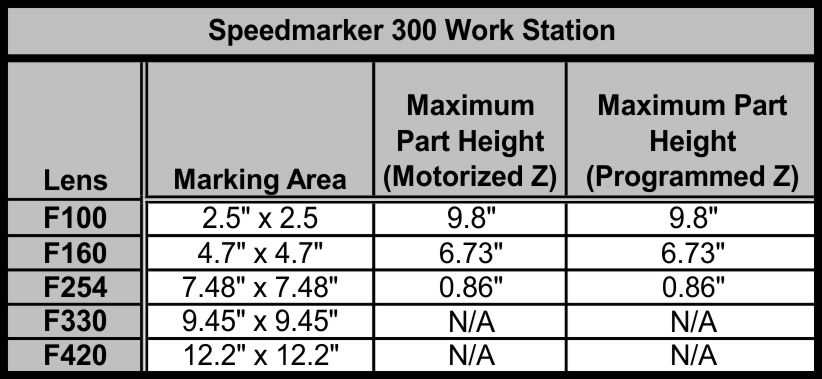

Lens Selection and Part Height

Lens selection is critcial.

Below are charts related to all lens configurations and the cooresponding maximum part heights

The Max Height, below, pertains to the workstation:

Focus Finder Option

Focus finder – elegant method to find focus using a secondary red dot. As the laser head is moved up or down, two red dots will seperate or come together. When the part is at the correct focus, the operator will see only one red dot on the part.

Focus finder – elegant method to find focus using a secondary red dot. As the laser head is moved up or down, two red dots will seperate or come together. When the part is at the correct focus, the operator will see only one red dot on the part.

Rotary Indexer:

Ring Marking Shown

OD and ID of rings are easily marked

Rotary Indexer allows 360 degree marking. Wrap logos, text and photos seamless around rings or cylinders! The rotray indexer tilts to allow marking on the inside of rings.

LWS Workstation and X and Y Motion

LWS Workstation includes wheels and is classified as an eye safe Class 2 laser system

LWS Workstation without top skins.

– Side to side is 30 inches across.

– Front to back is 38″.

– The T-slot tooling plate is 15.5″x14.5″. Picture shows tooling on top of the optional Y axis drive

LWS workstation top view with optional X axis motion. Laser shown in the left most position.

LWS workstation top view with optional X axis motion. Laser shown in the right most position.

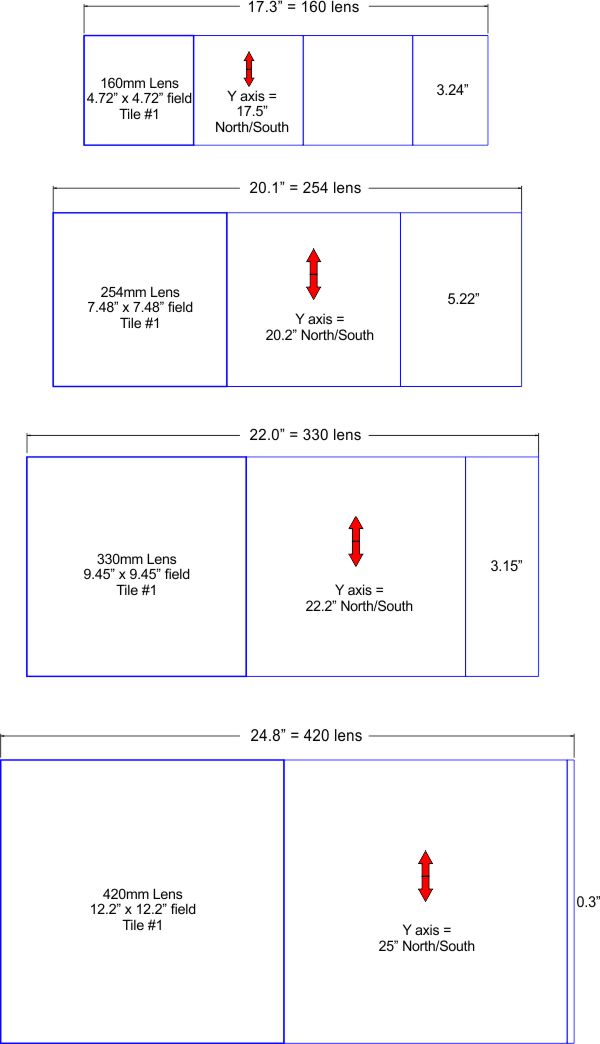

XY Options for LWS 700 and 1300 Workstations:

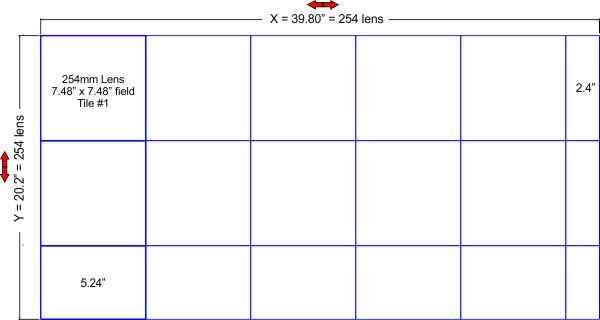

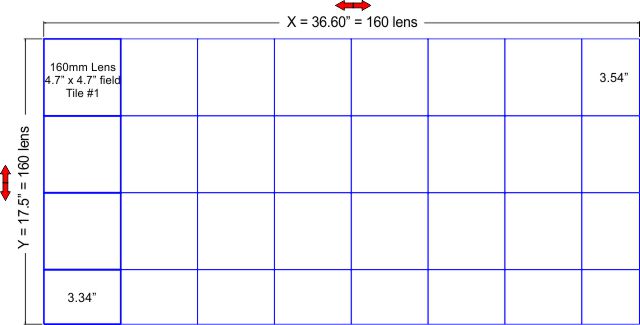

Each lens mark field equates to a “tile”

1st tile is far left. Laser moves left to right for larger “X” field

If “Y” motion is purchased, tooling plate with parts moves North and South for larger “Y” field

LWS 700 Workstation XY Options

Scroll to bottom for mock up # of tiles for Y axis

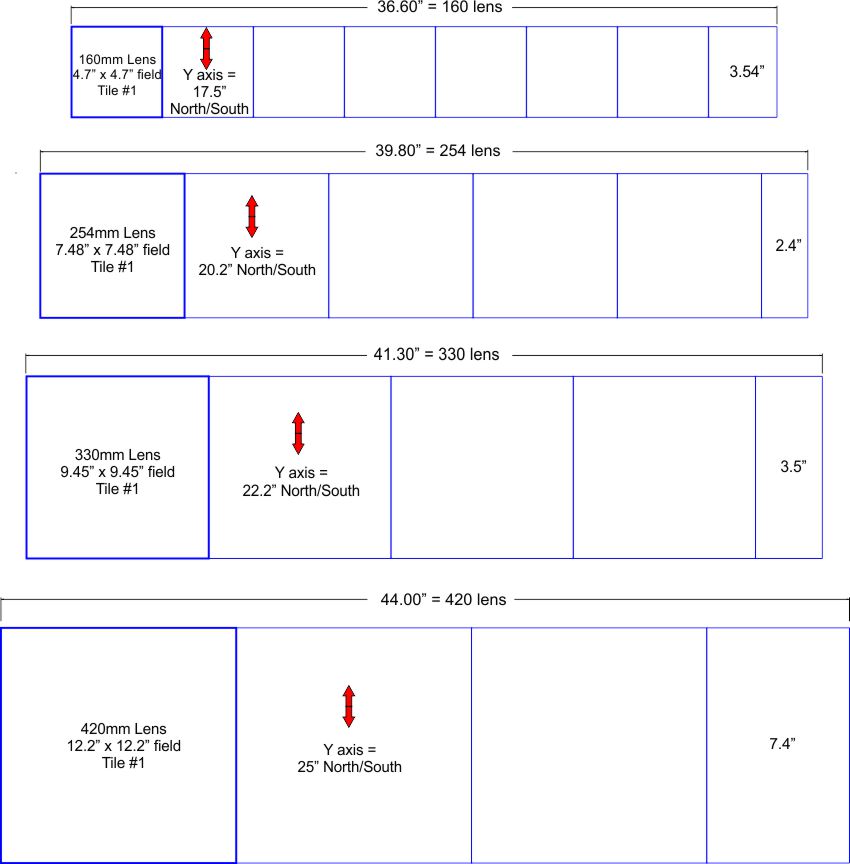

LWS 1300 Workstation XY Options

X Travel = 31.9″

Y Travel = 12.8″ (Optional)

XY Mock up for 160 lens LWS 1300

XY Mock up for 254 lens LWS 1300