Flatbed C02 Laser Cutting Tip…

Always be aware of FIRE when cutting, especially thicker materials when the beam becomes defocused and not enough air assist

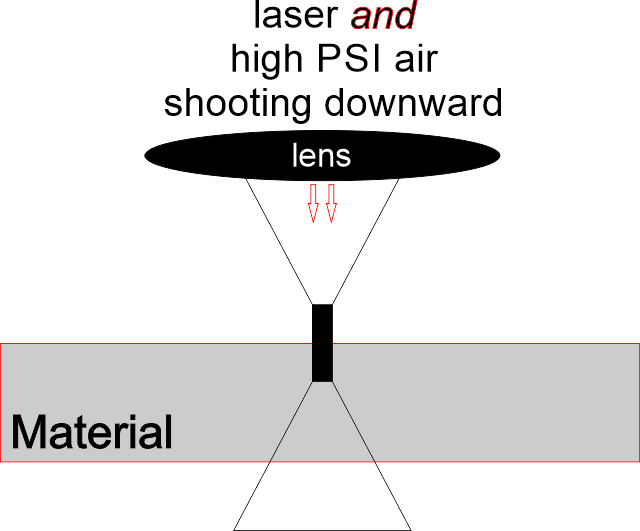

Flatbed or fixed head lasers are more appropriate for “cutting” than galvo because the material is closer to the lens. This means two things:

- A smaller lens with smaller spot can be used to better pierce through a material – like a surgeon’s scalpel

- This allows air or gas to push down on to the material to reduce or eliminate flames as well as help keep the material cooler and help the cutting process. This is not possible using a Galvo based laser

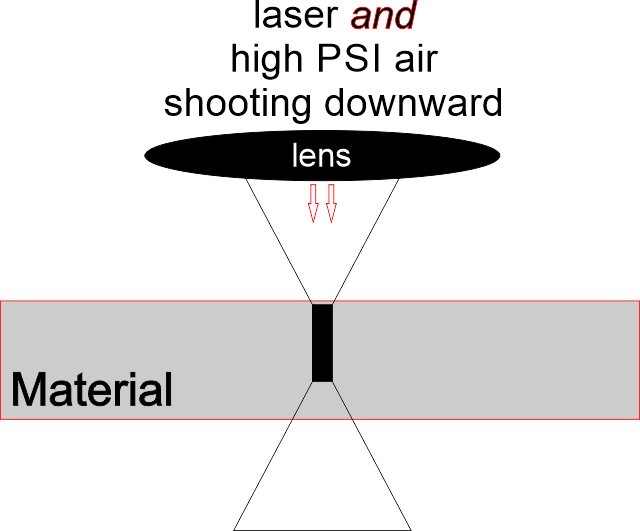

- Focusing on the top of a material is OK IF the material is thin. Thin is relative and depends on the laser used, wattage of laser, material, material thickness and lens size

- Extreme example: Using a flatbed CO2 laser, a 1.5″ lens and 1/2″ acrylic, the material may cut through if using high enough power but expect the bottom .25″ to be rough looking (chatter).

- Expect a non flat material edge due to the laser’s natural taper, as shown above

- Focusing below the material surface is helpful when cutting thicker materials. Focus depth is limited and will vary per lens.

- In the previous example, simply by raising the table or lowering the laser head (depends on the laser being used) can use more of the lens’ natural focus range. This will help with the “chatter” at the bottom and help keep a flatter material edge. If chatter is not eliminated then a larger lens can be used since it will have a better focus range – but be aware! at the cost of energy loss – so prepare to set the speed slower! Also, be aware the cut’s line width (Kerf) will also be wider. (more material will be removed because the larger lens focused spot will be larger.

- I typically like to re-focus halfway between the material top and the middle, especially using thicker material.

- Higher laser wattage helps to overcome focus issues. Higher wattage is a major consideration when purchasing the laser.

Note:

Beam width changes per lens, effecting resolution and beam energy. Energy is lost in a logarithmic fashion because the circumference of a circle is 3.14 (pi). Spot size times pi is the energy of the spot and is why higher wattage is necessary when using larger lenses, especially using the 4″ lens. This is also why a 30 watt CO2 laser using a 2.5″ lens has a hard time cutting through even .25″ wood or acrylic.

This is also part of the reason why a galvo laser is not very good at cutting. Galvos have a very different setup and galvo lens’ used are much larger since the process area is dictated by the lens.

Galvos have no chance for direct air pushing down on the material because the focus distance is much greater from the bottom of the lens to the top of the material