Blog

May 14, 2014

Laser - Marking, Engraving and Cutting Products

May 14, 2014

Laser Marking Metals

Category:General

Posted by: Gary

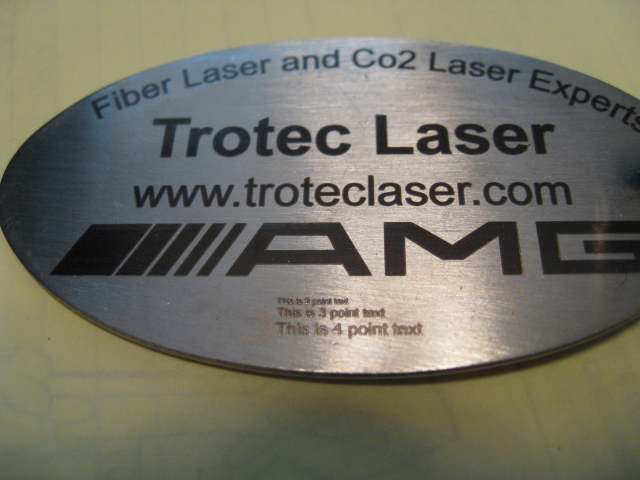

There are several lasers that may be used to achieve a dark mark on bare metals and the good news is the most common, CO2 and fiber lasers, are also the most cost effective. Both will achieve a contrasting mark, but in different ways, so if you already own of these lasers you are in good shape. The only viable marking method using a CO2 laser is using a secondary process called laser bonding. This is very common and has been around since the mid 1990’s. A material such as Cermark or Thermark is applied to the bare, clean metal surface, then lasered and then wiped clean. The result is an indelible permanent mark on top of the metal surface that will survive the harshest environments including UV rays from the sun. Cermark and Thermark are similar to each other and will “bond” to the surface of any bare metal. The resulting mark is black or a shade of black, depending on the specific type of metal. For instance, depending on the laser bonding material used, aluminum can result in a black to a dark grey and shiny metals such as mirrored finished steel will appear gray to the human eye. It is interesting that some companies will try to sell a CO2 to “directly mark” bare metal. Be aware as back reflections through the beam path can destroy power supplies. Also, your metal will become extremely hot and depending on the material thickness, may cause your metal to warp. The resulting time to mark will be very slow and the mark will look brown, at best.

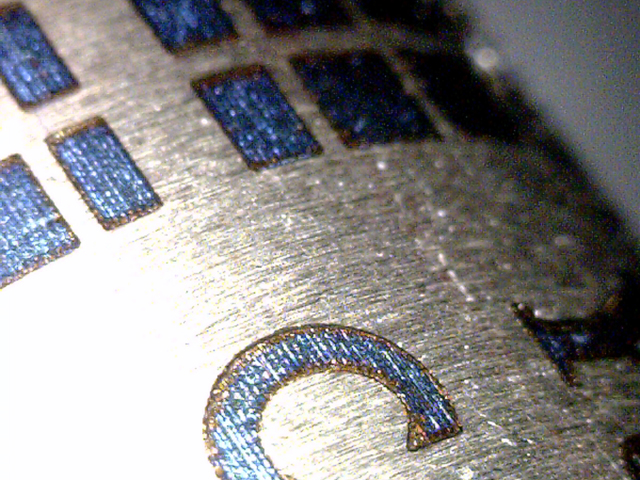

The fiber laser will mark metals directly and therefore save cost on the laser bonding consumables and labor to apply the bonding materials. Metals absorb the fiber laser energy and using desired laser settings different types of marks can be achieved. Black marks without removing material, aka “annealed mark” with the fiber laser can only be made on metals containing carbon such as steel ; however, nice contrast, engraved marks can also be made on other metals such as copper, brass and aluminum.

Stainless Steel Annealing – Marking without removing material using a fiber laser

Aluminum – Laser Bonded with Thermark tape using a CO2 laser

Brass – Deep engraving to create contrast using a fiber laser. Engraved Zeus in to an e_cig mod

Titanium – Marking without removing material. Fiber or YAG lasers can achieve yellow, red, blue and black marks simply by adjusting laser settings

Brass – Deep engraving to create contrast using a fiber laser. Engraved Zeus in to an e_cig mod